Geotechnical Drilling

Geotechnical Drilling is the most common, fastest and cheapest way of collecting information of geological structures. There are many types of Geotechnical drilling.

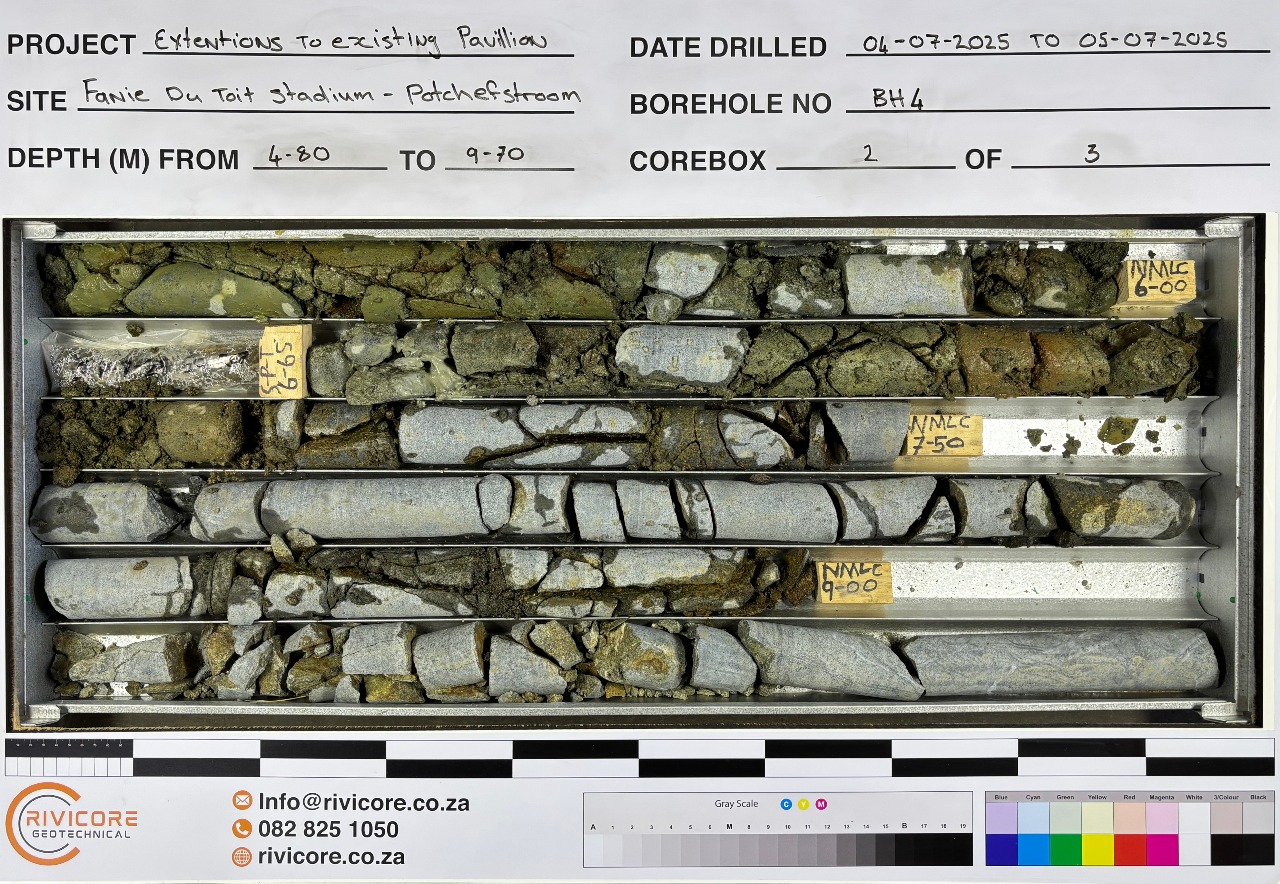

There are different types of Geotechnical Drilling such as Percussion Drilling, Sonic Drilling and Diamond Drilling. At Rivicore we currently provide Rotary Core Drilling (Diamond Drilling). The key technology of geotechnical drilling is the actual diamond bit itself. It is composed of industrial diamonds set into a soft metallic matrix. The bit is mounted onto a core barrel, which is connected to a drilling rig. Water is injected into the drill pipe, so as to wash out the rock cuttings produced by the bit and also to reduce the heat produced due to friction which causes less wear and tear of the bits. An actual diamond bit is a complex affair, usually designed for a specific rock type, with many channels for washing. Our triple tube core barrel has an inner tube that collects the samples at 1.5 meter intervals in order to provide high quality core presentation and orientation to its clients.

Geotechnical Drilling offers a number of significant advantages over conventional drilling. Cutting is more accurate than percussive techniques which means that there is less chance of damage which could affect structural integrity. Geotechnical Drilling requires less space and head room than other drilling methods.

Geotechnical Drilling has many uses and applications such as:

- Drilling for Foundation Purposes

- Underground Water Monitoring

- Pile Integrity

- Pile Contact Point

- Shallow Mineral Exploration

- Dam Wall Integrity

- Bridge Investigations

- Road Maintenance

These additional tests and extra’s goes hand in hand with Geotechnical Drilling to give you the most information out of your borehole.